Automated ICP Sample Preparation

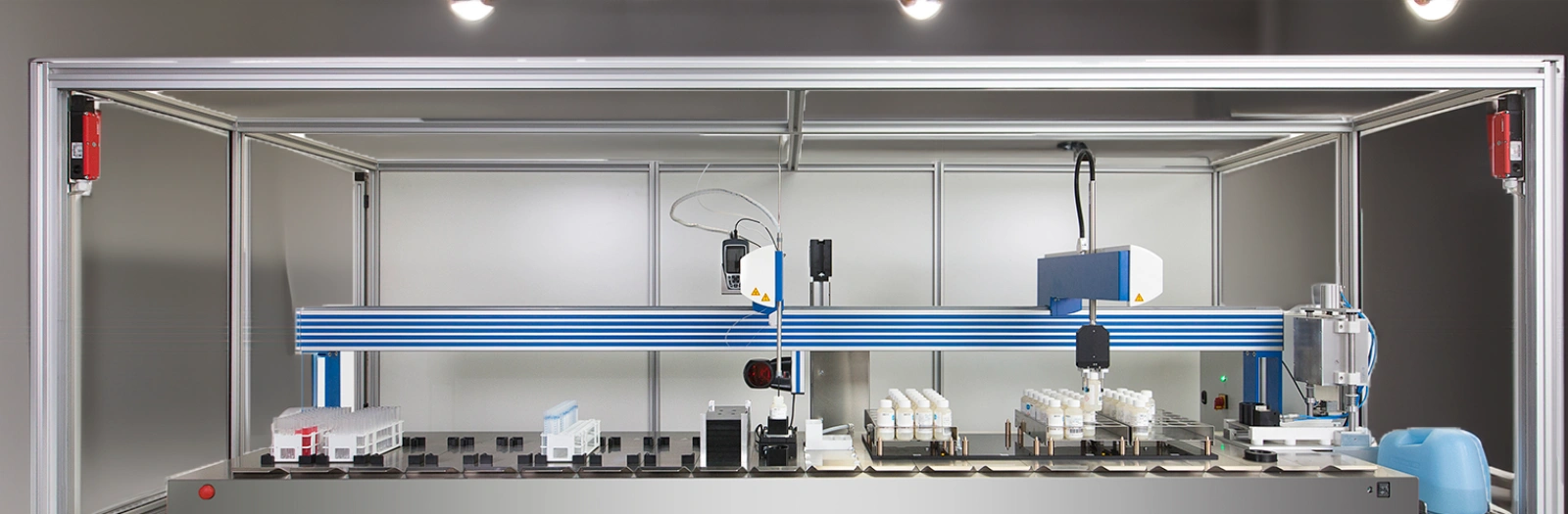

This application note describes an automated ICP sample preparation robot. Water samples need to be transferred from the sample taking containers to tubes, suitable for loading on the ICP auto samplers. In addition several steps are executed to ensure the transferred samples are of high quality and are ready for analysis.

The goal of this project was to streamline the transfer of water samples from sample taking containers into tubes suitable for ICP auto samplers. Key steps are meticulously executed to ensure the transferred samples meet stringent quality standards and are fully primed for accurate analysis. With a focus on enhancing workflow efficiency, enabling long-term sample storage, and facilitating complete track & trace capabilities, the Xperimate system used in this project excelled.

ICP Sample Preparation by the Xperimate

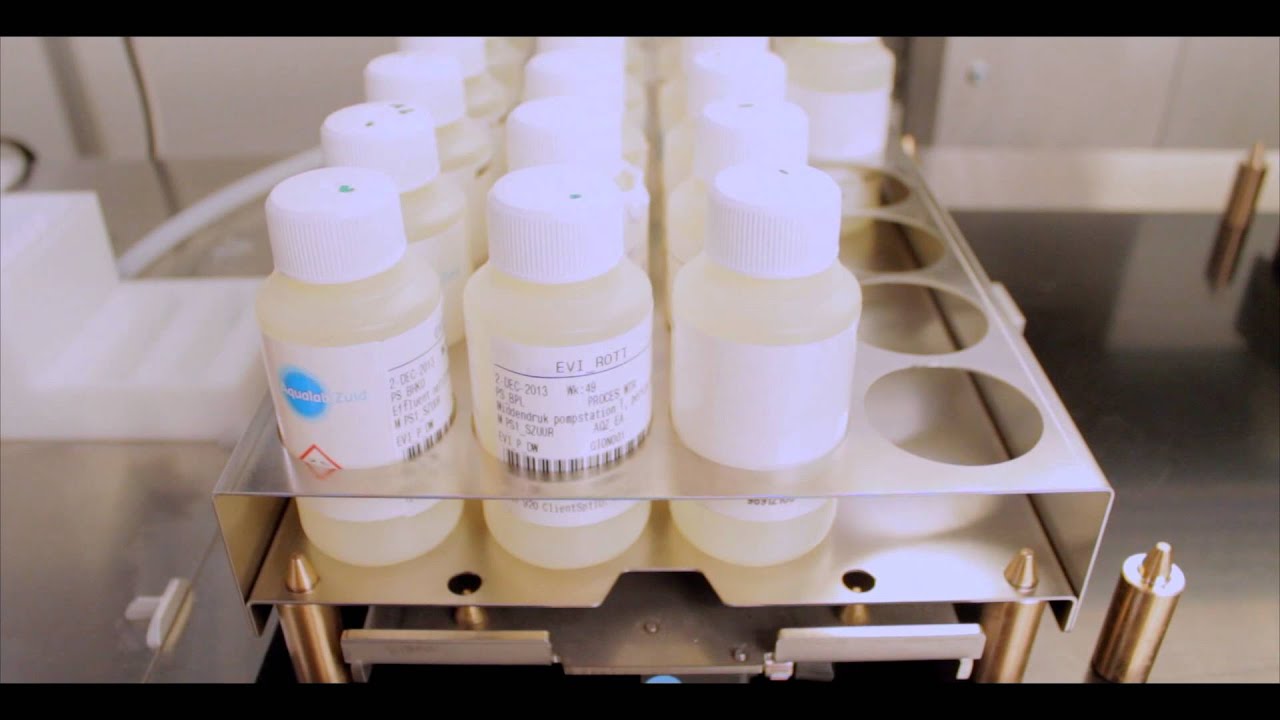

Step 1: Samples are loaded on the system by placing full racks on one of the four input positions. After completing this step, the automatic storage system will store each of the loaded racks internally and the system is ready for even more samples.

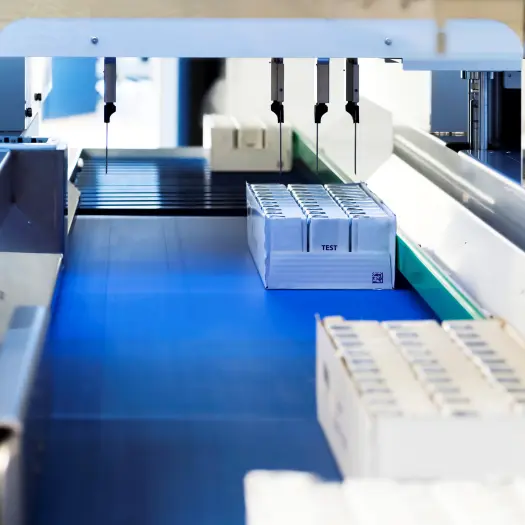

Step 2: The operator starts the process by clicking a button in the Xperimate software. The Xperimate software takes over the process now and starts loading one of the racks with new samples on the deck of the Xperimate pipetting robot.

Step 3: The Xperimate robot, scans the barcode of a new sample and places the sample on a shaker to homogenize the sample.

Step 4: The Xperimate robot decaps the bottle after homogenizing and places it back on the shaker.

Step 5: After decapping, an initial pH check is performed. The sample should have a pH lower than a setpoint set by the operator. This is the first quality check on the sample. If the sample does not pass this check, the sample is transferred to an error rack on the robot. After manual correction/inspection of the sample, the sample can be loaded again.

Step 6: The required sample volume is aspirated from the source bottle and during aspiration, an in-line turbidity check ensures the turbidity of the samples is below a specified value. If this is not the case, the aspirated sample is flushed out of the needle and the bottle is transferred to the error rack on the robot.

Step 7: Sample is dispensed in the destination ICP vial rack, taking into account locations for standards and controls.

Step 8: Sample is re-capped and transferred to a new storage rack for long-term storage in the integrated storage system.

Step 9: After all samples have been transferred to the ICP vial racks, worklists are exported for the various ICP racks and ICP analysers (Thermo, Agilent, etc.) allowing full sample track & trace throughout the process.

Re-analysis Process In case an ICP measurement is not performed correctly, or results need to be verified, the Xperimate software will automatically distribute the samples again from the storage system, to allow the operator to automatically measure the sample again.

Waste Separation After successful measurement of the sample has been performed and/or after a configurable storage time, samples can be removed from the storage system either by asking the software to eject the sample or to automatically separated the liquid from the bottles and dispose of them in liquid waste and solid waste separated.

IF WE CAN THINK IT, WE CAN MAKE IT

Discover Your Possibilities

Are you interested in exploring the potential of streamlining your workflow with Synchron's tailor-made automated solutions? Don't hesitate to get in touch with us to discover how we can optimize your ICP sample preparation process!

Key Features

Fully integrated sample storage system (up to 1200 samples, 100ml bottles)

Xperimate liquid handler for sample transfers

Initial pH and Turbidity checks

Capping/decapping

Shaking at a configurable speed

Integrated waste material separation