IF WE CAN THINK IT, WE CAN BUILD IT

Discover your possibilities

Do you want to know more about the seedpicking possibilities at Synchron? Or do you have an other agro challenge for our experts? Feel free to contact us.

Our AgBio product line is a range that has been designed as products rather than as a unique project. These products are designed by taking the requirements from several customers into consideration and packed into a single system. In the process from seed to data we have several solutions available.

For many process in the lab, seeds will have to be individualized for analysis or growth. This can be required for DNA extraction, germination, sowing, phenotyping and an range of other applications. Our SeedPickers will individualize seeds from multiple batches, fully automatically. This process is completely controlled by imaging, barcodes and vacuum measurements during each movement. Synchron offers several models, based on two di¬fferent platforms: a smaller 4-axis system and an industrial 6-axis arm. The larger system can easily be upgraded with more stacker capacity, a range of tools and modules and even be integrated into our conveyor based systems for further automating your process.

The SeedPicker systems allow for processing different types of seed within a single run with an almost 100% accuracy through the use of a special vacuum control on individual, auto changeable picking tools. For larger seed batch sizes, our soundwave controlled shaker can make every seed available to be individually picked as well as returning the unused seeds back into the original seed container. The software is comprehensive but can be adapted to specific customer needs.

Our SeedPicker family automates and controls the individualization of your seeds with great accuracy in a fully automated manner.

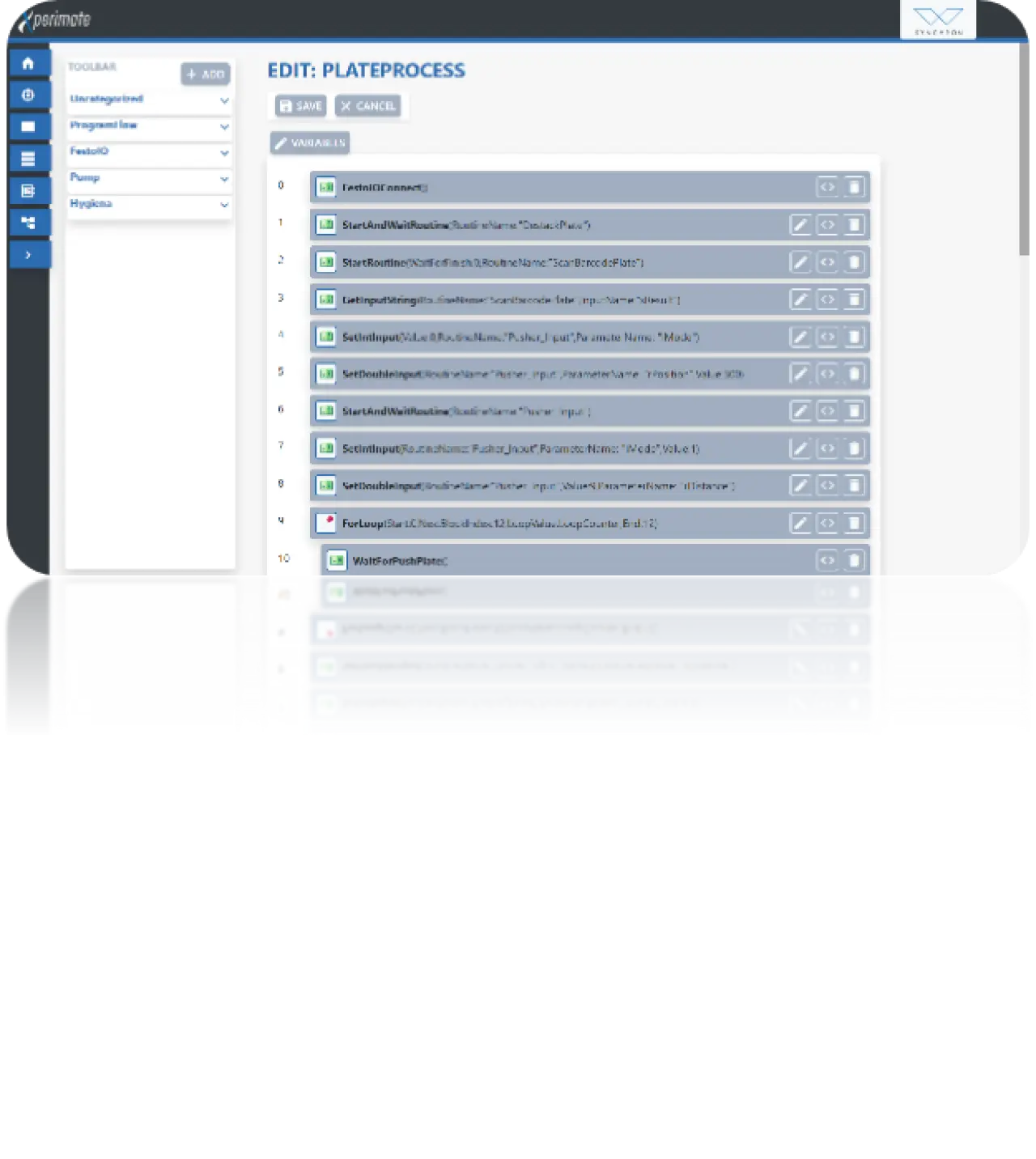

The SeedPicker is driven by Synchron’s proprietary Xperimate software. Xperimate controls most automation solutions created by Synchron and allows for a robust uniform approach for all systems. Xperimate is on one hand a development tool to create workflows on different levels of technical skills, but on the other hand a backbone to the HMI interface that operators will see and use. Systems powered by Xperimate benefit from years of development and proven performance across a varied hardware, applications and customer base.

Xperimate is created to control all kinds of robotics, instruments and other electrical equipment commonly found in lab automation. The software can be adjusted by adding modules allowing for a complete, but also expandable software setup.

In development mode Xperimate is a graphic user interface used to compose and optimize protocols. Xperimate has multiple user levels. The programming level allows the definition and optimization of every step in the application. In run mode the operator has access only to tools that allow for an easy and efficient user interface to set up a worklist, adjust parameters, start and stop a run and monitor the current status of the SeedPicker.

Figure 1 Xperimate method (workflow) editor

Figure 1 Xperimate method (workflow) editor

Figure 2 Simplified operator interface

Figure 2 Simplified operator interface

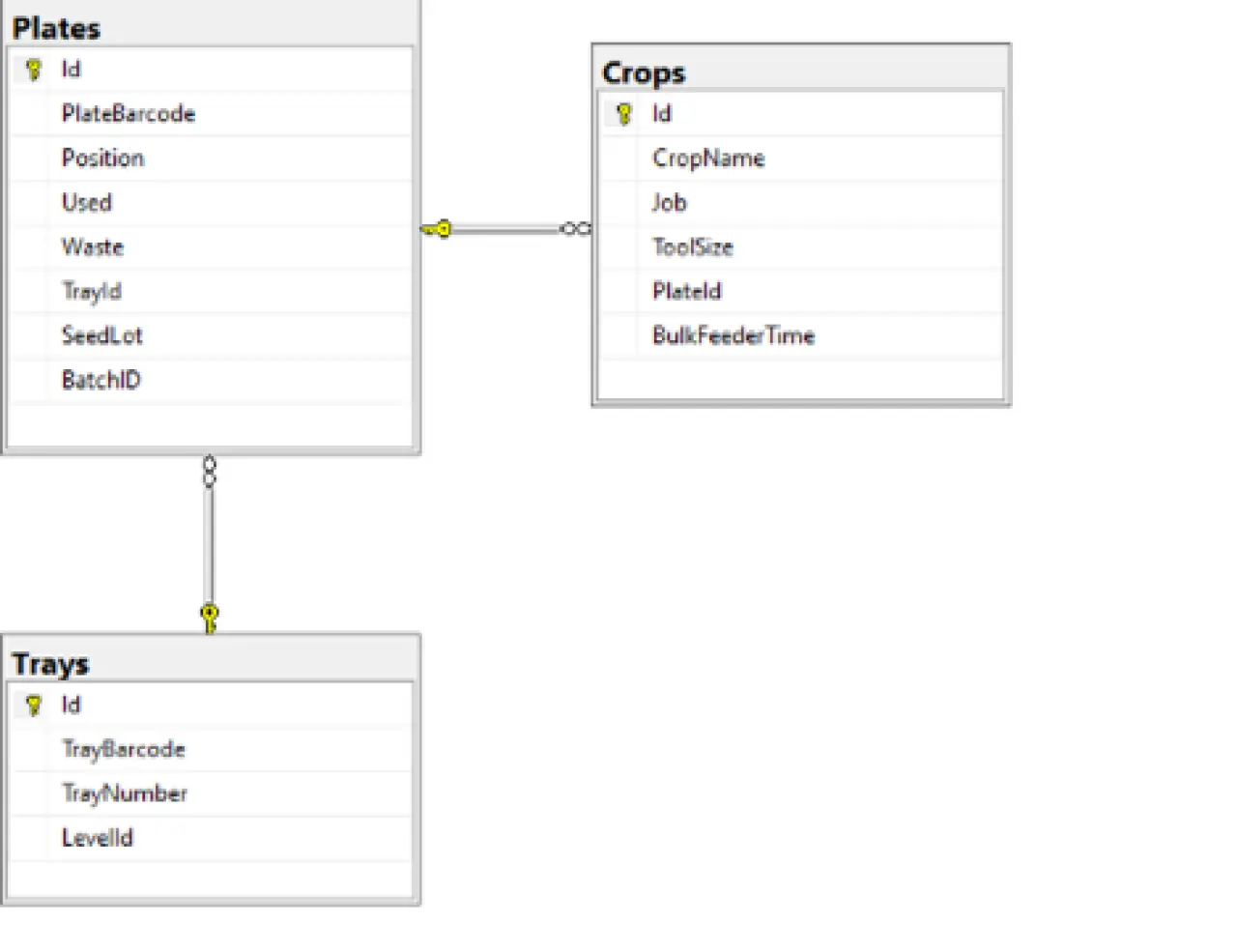

Database module

The Xperimate database module allows for data structure, storage and transfer. The SeedPicker is equipped with existing data structures which are explained below:

Seedlot (crop ID)

Tray (tray ID)

Sowing pattern

Figure 3 Database relation example

Figure 3 Database relation example

SeedPicker toolkit (selection)

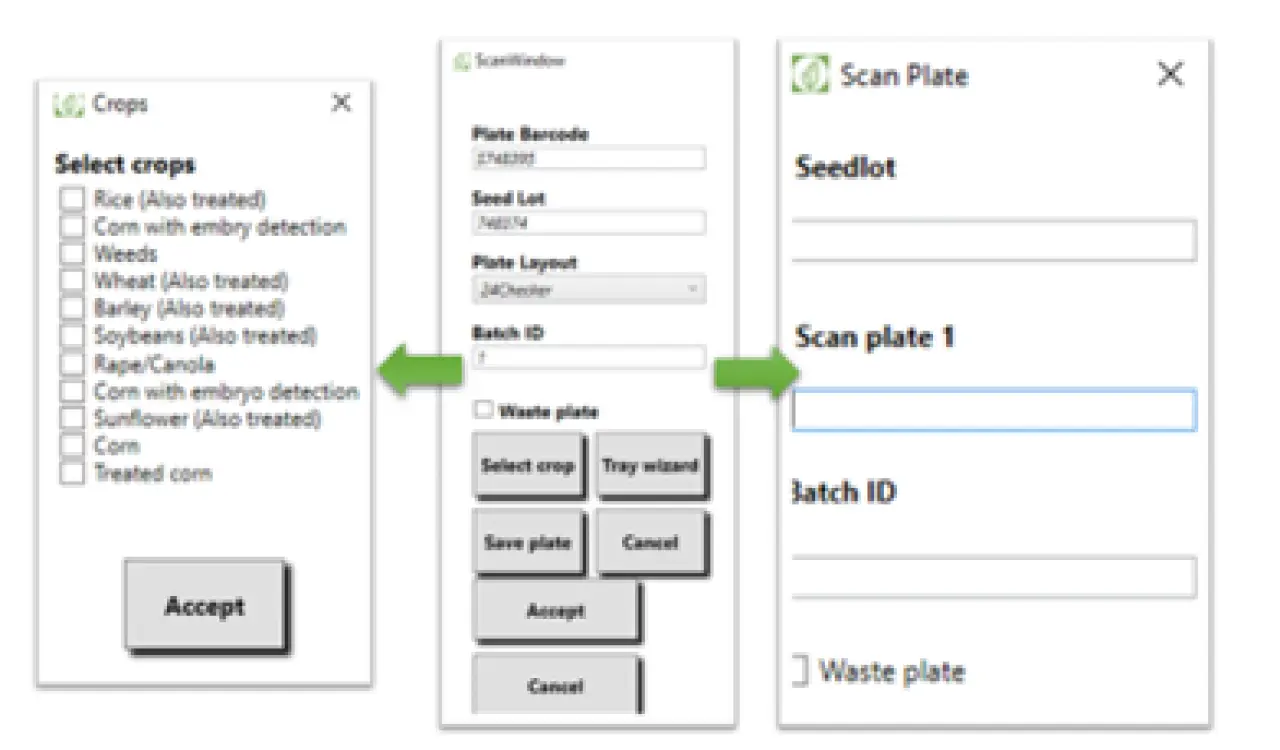

The SeedPicker is equipped with predeveloped tools that allow for flexible setup by the customer and operator. For this application the following tools are most important as they relate to the application aforementioned data structures.

Barcode Linking tool

The barcode linking tool allows for, as the name implies, linking information to its respective container or position. In this workflow it is used as follows: a sowing tray (barcode) will be filled with seeds from a seed container (barcode) which can be found in a position in the plate hotel (optionally barcode). The seeds in the seed container most likely come from a bag of seeds (optionally barcode) of a certain crop type. The linking tool makes sure that track and tracing throughout the process is possible by taking input from a handheld barcode scanner and guiding the user by means of a wizard.

Figure 4 Seedpicker barcode linking windows

Layout editor (sowing definition)

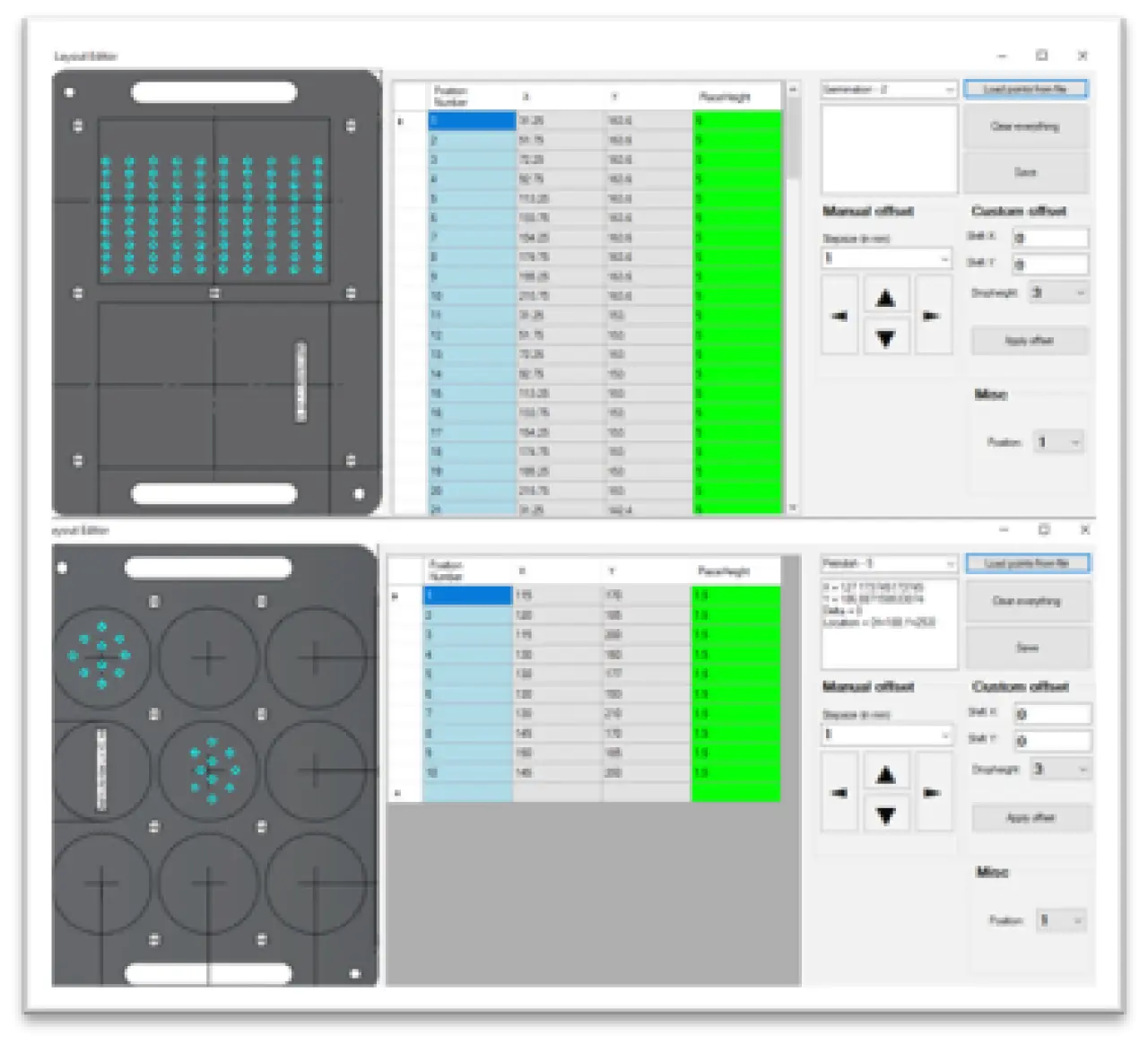

The layout editor allows for defining the pattern in which the seeds are placed. The editor can be setup for different formats. The SeedPicker is used in practice for placing seeds into all kinds of containers such as: microtiter plates in all formats up to 96 wells from shallow to deep well, tube racks, petri dishes, germination trays, sowing trays etc. the tool allows for coordinate definition by file (csv), simple tool calculations such as offset x/y, rows and columns, but also manual input by placing markers by hand. the tool can also be used to bulk edit and add single points.

Figure 5 Seedpicker layour editor

Figure 5 Seedpicker layour editor

Do you want to know more about the seedpicking possibilities at Synchron? Or do you have an other agro challenge for our experts? Feel free to contact us.

Trayfeeder

Denso 6-axis robot arm

Tool racks

Asyril Shaker

Bulk Feeder

Cognex Camera

Control PC